VU Manufacturing offers a variety of services for users of “soft-trim” and plastic products. Our range of service can begin at the prototype level making one to a few parts, low volume or high volume of simple or multiple component assemblies.

SERVICES

DESIGN

Our engineers and creative people will work with you to make your ideas into reality.

DEVELOPMENT

We blend “craftsmanship” with modern technology.

PROTOTYPE

Prototype parts that reflect production-like manufacturing.

PRODUCTION

Product Development, Process Development, Pattern Development, Material Optimization, NC Cutting, Die Cutting, Sewing (Hand, Manual, Programable), Wrapping (Hand, Automatic), Assembly, and Plastic Injection Molding.

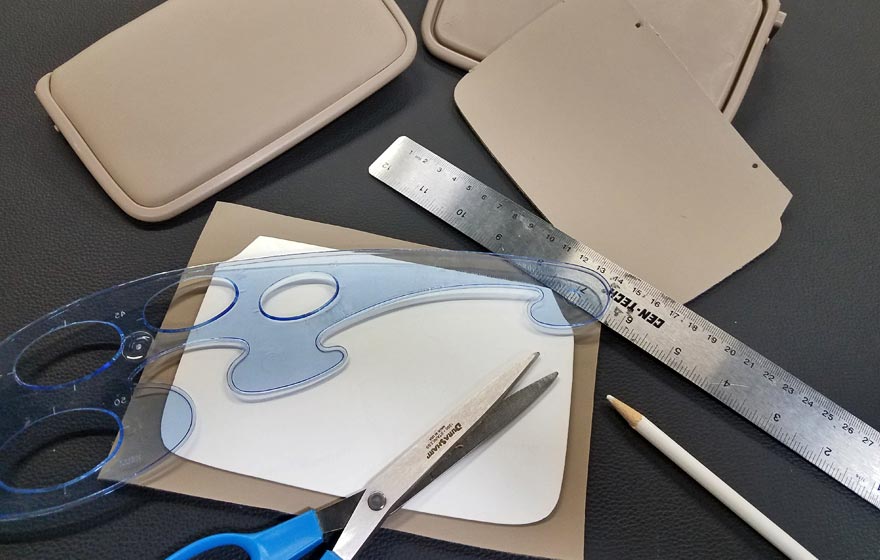

Development

It starts with interpreting the customer’s guidelines. Considerations towards; volume, materials, feel, look, alignment, environment, all awhile understanding the end users expectations. The aforementioned elements assist our engineers in determining feasibility and methodology to be used when processing the final product.

Being “soft-trim” refinement is part of the development process. To ensure both parties achieve their individual expectations, we encourage “early samplings”. This can be 3-D models or multiple prototypes off simple molds. VU Manufacturing works with highly skilled prototype and tooling sources which can be contracted to aide in design and all methods of tooling.

Our development team maintains involvement through transition to the production team and production launch, ensuring the customer’s voice is understood.

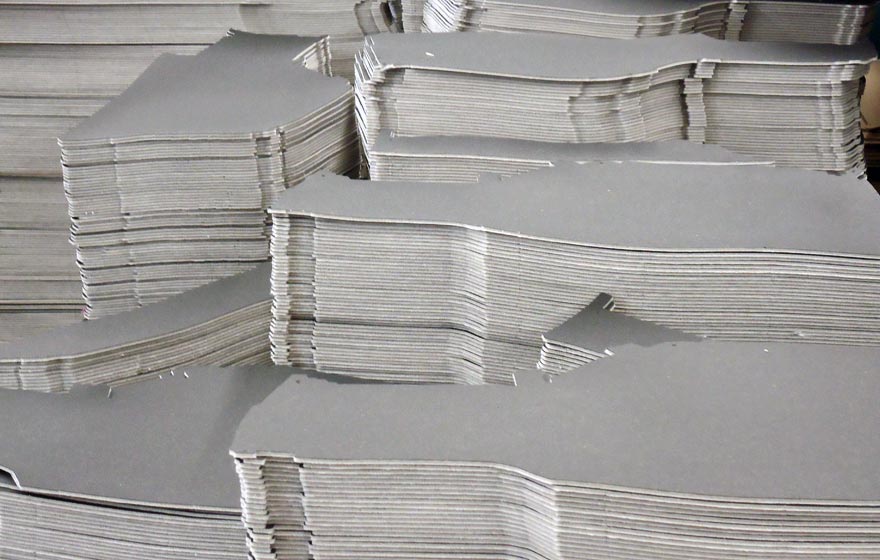

Cutting

VU Manufacturing offers multiple cutting options; hand, die and programmable NC cutting. The products volume traditionally dictates the method employed. In all cases VU’s engineers are either provided a pattern from the customer or internally, we develop the pattern. This pattern is then digitized into the latest software technology which calculates the best nesting and optimum utilization of material.

Sewing

VU Manufacturing offers hand, single-needle, double-needle and programable machines that satisfy most requirements.

Wrapping

Wrapping components is more of an art than a science. VU Manufacturing employs a series of training methods to ensure our operators become proficient in all methods involved in wrapping. Some but not all techniques involve edge wrapping, corner softening, back folding, isolated adhesive application, stapling, sonic staking, seam alignment, etc…

Assembly

VU Manufacturing provides a variety of assembly options; hand, cold and hot bladder, compression, vacuum along with a variety of ancillary hand operations such as riveting, screw assembly, sonic welding and staking. Scanning, sensors, camera’s in conjunction with poke yoke are employed to ensure expectations are met. Operators go through a series of training methods to ensure they understand the operation and they are proficient in their skill level.

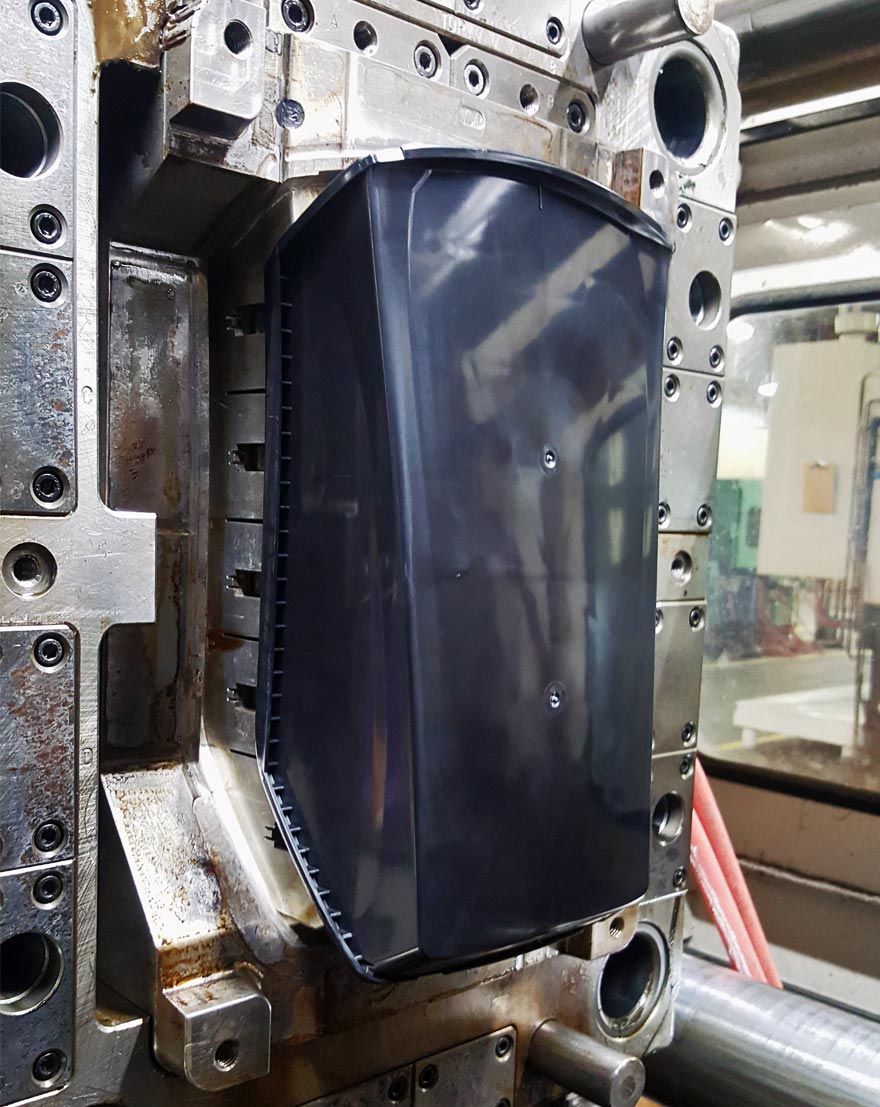

Injection Molding

VU Manufacturing expanded its’ capabilities to include injection molding of plastics (VU Plastics). VU Plastics has injection molding machines ranging from 75-600 tons. This added capability offers us flexibility in satisfying our customers and VU Manufacturing’s internal needs.